When you buy a new electric car, a medical device, or even a smartphone, you expect it to work perfectly. You don’t think about the thousands of checks, scans, and measurements that went into making sure it didn’t fail. But if it does fail-if the battery overheats, the sensor glitches, or the part cracks after three months-that’s when you start asking: Why did this happen? And more importantly, who’s to blame?

The truth is, manufacturing isn’t just about building things anymore. It’s about managing fear. Fear that a single defective part will trigger a recall. Fear that a supplier’s mistake will damage your brand’s reputation. Fear that your customers will stop trusting you altogether. In 2025, quality assurance isn’t a back-office task. It’s the invisible hand holding your brand together-or tearing it apart.

Quality Isn’t a Process. It’s a Promise.

Most people think quality assurance means checking parts at the end of the line. That’s outdated. Today, it’s about preventing problems before they happen. Companies like ZEISS and Hexagon now use AI-powered systems that scan components in real time, catching flaws invisible to the human eye. One automotive supplier in Michigan reduced defects by 37% after installing AI inspection software. That’s not just efficiency. That’s trust built into the product.

But here’s the catch: technology alone doesn’t fix quality. A company spent $2.3 million on automated inspection tools, trained no one, and ended up with 40% more errors. Why? Because machines don’t understand context. They need people who know what to look for, why it matters, and how to respond. The best quality systems combine sensors with skilled operators who can interpret data, not just follow alerts.

The Real Cost of a Mistake

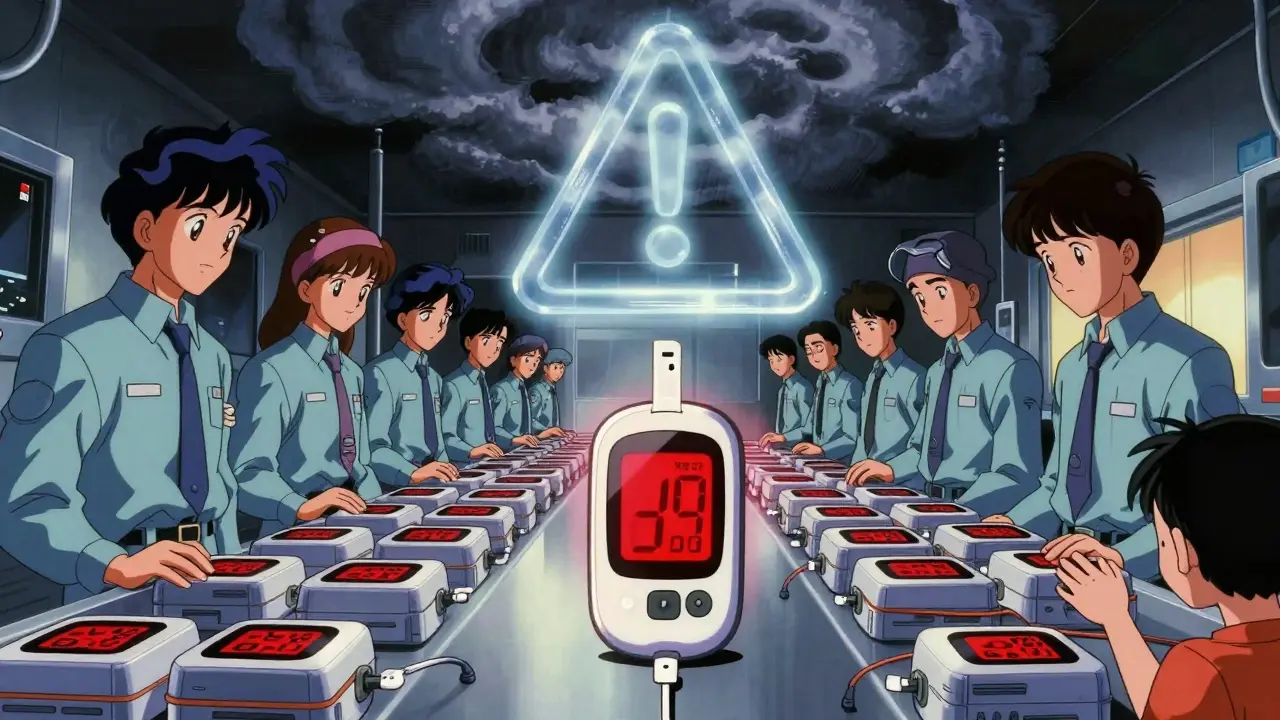

Let’s say a medical device manufacturer ships 10,000 glucose monitors. One in 500 has a faulty sensor. That’s 20 devices. Sounds small. But if three of them give wrong readings, someone could die. The company faces lawsuits, a federal investigation, and a public backlash. Their brand, built over decades, starts to crumble. The rework cost? $1.2 million a year, according to one case study. The reputational damage? Impossible to calculate.

Manufacturers now see quality as a direct line to profitability. Forty-four percent say rising material costs are their biggest headache. Thirty-eight percent say rework and iterations are eating into margins. That’s why precision matters. A single millimeter off in an electric vehicle battery casing can mean the difference between a safe product and a fire hazard. There’s no room for guesswork anymore.

Supply Chains Are Fragile. Brands Are Not.

When a supplier in Taiwan delays a critical chip, it doesn’t just slow down production. It triggers a chain reaction. Machines sit idle. Workers get laid off temporarily. Customers cancel orders. And the brand? It gets blamed-even if the fault wasn’t theirs.

Leaders who survive this chaos treat suppliers like part of their own team. They share forecasts. They send engineers to audit factories. They co-develop quality standards. One company in Ohio saw 31% more supply chain resilience after doing this. Their competitors? They kept signing contracts and hoping for the best. When the next disruption hit, they were the ones scrambling.

Brand psychology doesn’t care who’s at fault. Customers see your name on the product. That’s who they hold responsible. If you don’t control your supply chain, you’re letting strangers make promises on your behalf.

The Skills Gap Is a Brand Risk

Forty-seven percent of manufacturers say they can’t find skilled workers. Not just engineers. Not just technicians. People who understand both old-school quality checks and new digital tools. This isn’t a hiring problem. It’s a survival problem.

Quality engineers who know how to read AI-generated data now earn $98,500 on average-22% more than those who don’t. Yet, 63% of manufacturing professionals on LinkedIn say they struggle to find staff trained in both worlds. The result? Companies invest in smart systems, then let untrained workers operate them. The data looks good on paper. But in real time, mistakes slip through.

Think about it: if your customer service team doesn’t understand why a product failed, they can’t explain it to your customers. If your marketing team doesn’t know the real story behind your quality claims, they can’t communicate them honestly. That’s where brand trust breaks down-not in the factory, but in the conversation.

Cloud-Based Systems Are Changing the Game

Five years ago, quality data lived in spreadsheets, paper logs, and isolated software. Today, cloud-based Quality Management Systems (QMS) connect every department-from procurement to customer support. In 2025, 68% of new enterprise deployments use cloud QMS, up from 52% in 2023.

Why? Because when a defect is found in California, the team in Germany sees it instantly. When a supplier’s batch fails, the whole network gets flagged. No more silos. No more surprises. And when customers report an issue, the system traces it back to the exact machine, shift, and material lot. That’s transparency. And transparency builds trust.

Brands using these systems report 22% lower rework costs and 18% faster time to market. But here’s what’s not talked about: they also get 41% fewer customer-reported defects. That’s not just cost savings. That’s customer loyalty.

The Divide Is Growing

Not all manufacturers are keeping up. Aerospace and medical device makers are at 78% and 72% adoption of advanced quality tech. General manufacturers? Only 48%. That’s not just a gap in technology. It’s a gap in future-proofing.

Companies clinging to manual inspections are paying 43% more in labor costs. They’re slower. They’re less accurate. And they’re more likely to miss a defect that leads to a recall. Meanwhile, early adopters of predictive analytics are seeing 27% fewer quality deviations reach the customer. Forrester warns: manufacturers who delay AI-driven quality tools will face 23% higher defect rates by 2027.

This isn’t about being cutting-edge. It’s about staying alive. The brands that win in 2030 won’t be the ones with the biggest factories. They’ll be the ones with the most reliable products-and the most trusted names.

What Happens When Quality Fails?

Imagine you’re a parent buying a baby monitor. You pick a brand because it’s well-known, safe, and recommended. Then, the camera stops working after six months. You call support. They say it’s a ‘known issue’ and offer a replacement. But you don’t trust it anymore. You tell your friends. You leave a review. You switch brands.

That’s brand psychology in action. One failure doesn’t ruin a company. But repeated failures? They turn customers into critics. And critics become the new marketing team-for your competitors.

Manufacturers who treat quality as a compliance checkbox are already losing. The ones who treat it as a core promise-delivered consistently, verified transparently, and communicated honestly-are the ones building lasting brands.

The Future Isn’t Just Better Machines. It’s Better Trust.

In 2025, quality assurance is no longer about meeting standards. It’s about exceeding expectations before customers even know what they are. It’s about turning fear into confidence. Not by shouting about your certifications, but by proving your reliability every single day.

The brands that understand this won’t just survive. They’ll lead. The ones who don’t? They’ll fade into the noise of recalls, reviews, and rebrands.

Quality isn’t a department. It’s the foundation of every customer relationship. And in a world where trust is harder to earn than ever, it’s the only thing that lasts.

anthony epps

December 15, 2025 AT 20:54I never thought about how much goes into making sure my phone doesn’t explode. Now I’m kinda scared to buy anything new.

Dan Padgett

December 17, 2025 AT 14:28Quality isn’t just a checklist-it’s the quiet hum of responsibility echoing through every bolt, every wire, every silent promise made to someone who just wants their life to work without glitching. We build machines, but we sell trust. And trust? It cracks louder than any circuit board.

Hadi Santoso

December 19, 2025 AT 12:26so like… i work at a small shop that makes drone parts and we just got this new ai camera thingy. looks fancy but honestly? the guy who’s been here 20 years still catches more stuff than the machine. he just *knows*. machines don’t smell when something’s off. humans do. also, my boss spent 10k on software and didn’t train anyone. now we got 3x more rejects. lol.

Kim Hines

December 21, 2025 AT 04:36Every time I see a recall notice, I think about the person who had to sign off on that batch. What were they thinking? What pressure were they under? It’s not just about tech-it’s about culture.

Randolph Rickman

December 22, 2025 AT 00:52Look, the data doesn’t lie. Companies using cloud QMS are cutting rework by 22% and getting 41% fewer customer complaints. That’s not magic-that’s discipline. If you’re still using spreadsheets and hoping for the best, you’re not just behind-you’re a liability. Get with the program. Your customers aren’t waiting.

Tiffany Machelski

December 22, 2025 AT 13:48i read this whole thing and now i dont trust anything. not even my toaster. also i think the spelling on page 3 is wrong but i cant find it again. sorry.

SHAMSHEER SHAIKH

December 23, 2025 AT 07:45Let me be unequivocally clear: The erosion of quality assurance is not merely an operational failure-it is a moral collapse of corporate conscience. When we outsource integrity to algorithms without cultivating human wisdom, we do not innovate-we industrialize negligence. The $98,500 quality engineer? She is not a cost. She is the last bastion of ethical manufacturing in a world that has forgotten how to care.

Dave Alponvyr

December 25, 2025 AT 04:04So we spend millions on AI to catch defects… but can’t pay a human $25/hour to look at a part? Brilliant. Let’s just automate the blame too.

Joanna Ebizie

December 26, 2025 AT 04:24Anyone else think this is just corporate fluff? The real problem is CEOs who don’t want to spend money on workers. They’d rather buy a $2M robot than give a technician a raise. Then they wonder why things break.

Elizabeth Bauman

December 27, 2025 AT 03:25Did you know China’s state-run factories have zero recalls because they don’t use ‘foreign AI’? They use discipline. And pride. And they don’t outsource to Taiwan. This whole ‘cloud QMS’ thing? It’s just a Trojan horse for foreign control. We’re letting our own safety be managed by servers in Singapore. Wake up.

Dylan Smith

December 29, 2025 AT 00:43I work in customer service and we get calls every week about ‘known issues’ that marketing never told us about. We’re the ones apologizing while the factory keeps shipping the same broken parts. Someone needs to connect these dots before someone gets hurt

Colleen Bigelow

December 30, 2025 AT 07:07They’re lying. The real reason they’re pushing AI and cloud systems is so they can track you. Every time you report a defect, they log your IP, your location, your buying habits. This isn’t about quality-it’s about surveillance capitalism. And your baby monitor? It’s probably listening to your kid cry while sending the data to a server in Berlin. You’re not buying a product-you’re signing a spy contract.

sue spark

December 30, 2025 AT 20:13This made me feel hopeful. We’re not doomed. If we invest in people and tech together, we can build something that lasts. I’m going to tell my cousin who works at a factory to push for training. Small steps, right?